We build ROI-based business cases before projects begin — quantifying improvements in throughput, delivery accuracy, working capital, and production stability.

Maximise delivery reliability and profit — across complex, multi-stage production

AI-powered operational solutions that elevate human capabilities — increasing output, reducing disruptions and downtime, shortening lead times, and freeing up working capital.

- Improve delivery reliability without costly buffers

- Respond quickly to production changes and disruptions

- Reduce unexpected costs like rush deliveries and overtime

- Boost throughput and asset utilisation

Trusted by leading manufacturers | 30+ years of industry expertise

Business impact on Manufacturing companies

Improve your financial performance and competitive position

Improve delivery reliability

Advanced production planning (APS) and execution (MES) optimise material flow and create realistic schedules that adjust to actual capacity and disruptions.

The impact:

- >95% delivery accuracy

- -20% lead times

- Improved customer satisfaction and reduced cost associated with delivery issues

Increase operational efficiency

Real-time monitoring combines equipment data with operator insights to improve OEE, prevent downtime, and enable quick anomaly detection. Preventive maintenance optimises uptime.

The impact:

- +15% increased throughput

- Improved OEE and uptime

- Increased throughput and machine utilisation

Reduce tied-up capital

Improved planning accuracy reduces inventories and material buffers. Accurate forecasting decreases costs tied to inventory while maintaining on-time delivery.

The impact:

- -10% inventory costs

- Reduced inventory and buffer stocks

- Less waste

REPORT

Delivery reliability is the most important competitive advantage for European machineries

According to our 2025 European manufacturing study, companies that master delivery reliability unlock three critical outcomes:

-

increased market share through customer trust

-

improved profitability through efficient operations

-

strengthened business agility in navigating disruptions.

Operational excellence across your entire manufacturing value chain

We work with you across every stage — production planning, shop floor execution, equipment maintenance, and performance monitoring — to optimise your entire operation with modular solutions, professional services, and long-term partnership.

Connect all operational layers from strategy to daily execution

Many manufacturers face a critical disconnect: production plans don't reflect shop floor reality. Schedules live in spreadsheets, execution happens ad hoc, and operations run on instinct rather than data.

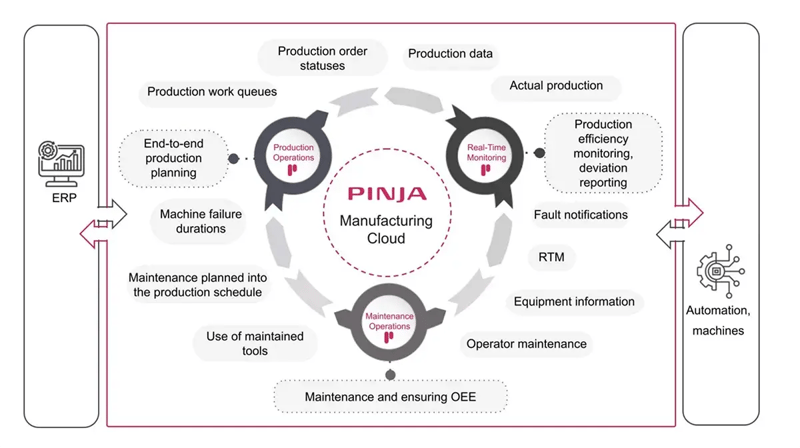

Pinja Manufacturing Cloud connects operational layers across planning, execution, monitoring, and maintenance — linking strategy with day-to-day production reality.

Plans inform execution. Shop floor data feeds back into planning. Teams gain a shared operational picture that supports better, faster decisions.

Rather than replacing every system, Pinja brings key operational capabilities together and integrates with existing environments — creating a continuous feedback cycle between planning, execution, and improvement.

Why all three together matter

- Optimised maintenance timing improves both production output and equipment health.

- Connected monitoring shows whether plans, maintenance, and execution truly align — exposing bottlenecks instantly.

- Better cross-team communication ensures production and maintenance work toward shared performance goals.

- Full transparency enables correct prioritisation of tasks and faster problem-solving.

- True OEE improvement by addressing all components: availability, performance, and quality.

How it works in practice

Demand planning (Sales Planning) → Demand forecasts and production volumes become clear targets and material requirements.

Production scheduling (Production Operations - APS) → AI-optimized schedules translate strategy into executable plans—accounting for capacity, materials, and real-time constraints.

Shop floor execution (Production Operations - MES) → Operators follow prioritized work queues. Real production data flows back automatically.

Real-time visibility (Real-Time Monitoring) → Equipment data combines with operator insights. Quick anomaly detection enables data-driven decisions.

Equipment reliability (Maintenance Operations) → Maintenance planned into production schedules. Preventive work prevents costly breakdowns.

For manufacturers of all sizes

Companies with complex, multi-stage production requiring precise delivery reliability and capacity optimisation.

Facilities running continuous or batch production where downtime causes material waste, bottlenecks, or quality issues.

Operations managing diverse product lines with varied production requirements and tight delivery schedules.

Why leading manufacturers choose Pinja

Clear scope, timeline, and pricing from day one. Standardised implementations ensure predictable progress and measurable business outcomes.

We combine APS, MES, real-time monitoring, and maintenance to manage production operations in a controlled way.This improves output, prevents disruptions, and ensures planning and execution align with real conditions.

Our ISO 27001–certified operating model covers development, hosting, support, and service delivery — meeting strict security requirements for global manufacturers.

Your 4-step journey from opportunity to sustained success

Success stories from our customers

From 4 days to 2 hours — Promeco speeds up production planning

Read the success story →

Read the success story

Purso unlocks hidden capacity and improves delivery reliability

Read the success story →

Read the success story

Get the insights, ROI clarity, and capabilities you need to move forward

Learn what it costs not to act, what top manufacturers achieve and how your operation compares to industry benchmarks.

All solutions run on the Pinja Fusion platform.

Your data flows seamlessly, your AI agents work across operations, and you have one partner accountable for everything.

-

Unified operational data

-

Modular solutions with shared components

-

Embedded AI for planning, forecasting, and diagnostics

-

Secure, scalable cloud foundation

Manufacturing Cloud — Modular solutions for every part of your business

Your operation is unique. You get configurable cloud subscriptions adapted to your workflows, solutions proven over 15+ years in manufacturing operations, and hands-on implementation from people who know your industry.

Improve delivery reliability in complex production. Advanced planning (APS) and execution (MES) optimise schedules and guide shop floor work.

Explore solution →

Plan sales volumes and production with reliable forecasts. Automated demand forecasting shows inventory development and recommends optimal production quantities.

Explore solution →

Reduce downtime with proactive maintenance. A CMMS that keeps maintenance one step ahead to protect throughput and control costs.

Explore solution →

Track production and improve efficiency. Real-time data monitoring combines equipment insights with operator input to improve OEE and prevent downtime.

Explore solution →

We take care of IT infrastructure, integrations, and custom software development. Free up your resources to focus on your operation.

Explore solution →

Our analysts transform your raw data into actionable reports. Turn your data into insights for optimisation, cost control, and growth.

Explore solution →

SUSTAINABILITY

Make sustainability your competitive advantage

Stricter regulations and consumer demands push manufacturers to adopt greener practices and achieve net-zero emissions. Pinja’s solutions help you track energy consumption, reduce waste through optimised production, and report on sustainability metrics.

Explore our latest news, blogs, guides and webinars

-

All

-

News

-

Blogs

-

Guides

-

Webinars

Download guide →

Read the blog

Read the blog →

Read the blog

Read the blog →

Read the blog

Watch the webinar→

Watch the webinar

Download guide →

DownloadSpeak directly with an industry specialist

Book time with Henna Landen for a brief, high-impact discussion on improving your delivery reliability.

Whether you're relying on costly buffer stocks to maintain delivery promises or struggling with production disruptions, Henna Landen can show you how specialised expertise and digital tools translate into measurable ROI.

Henna Lankinen

henna.lankinen@pinja.com

Schedule a chat with Henna